A great solution more than a simple boring bar!

State of the art high precise CNC-technology – with a winning performance

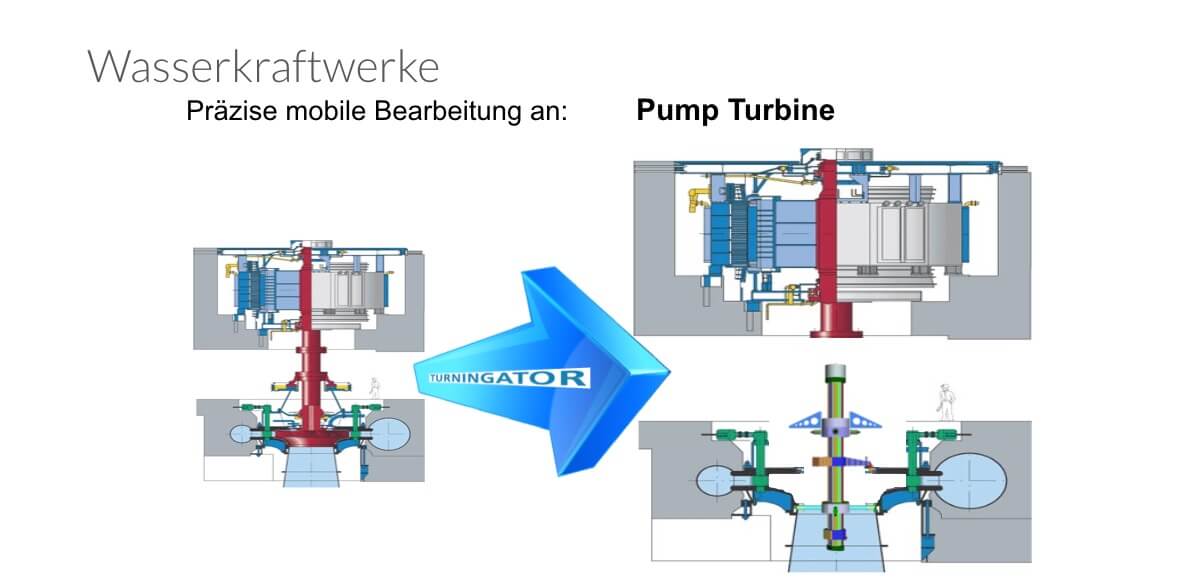

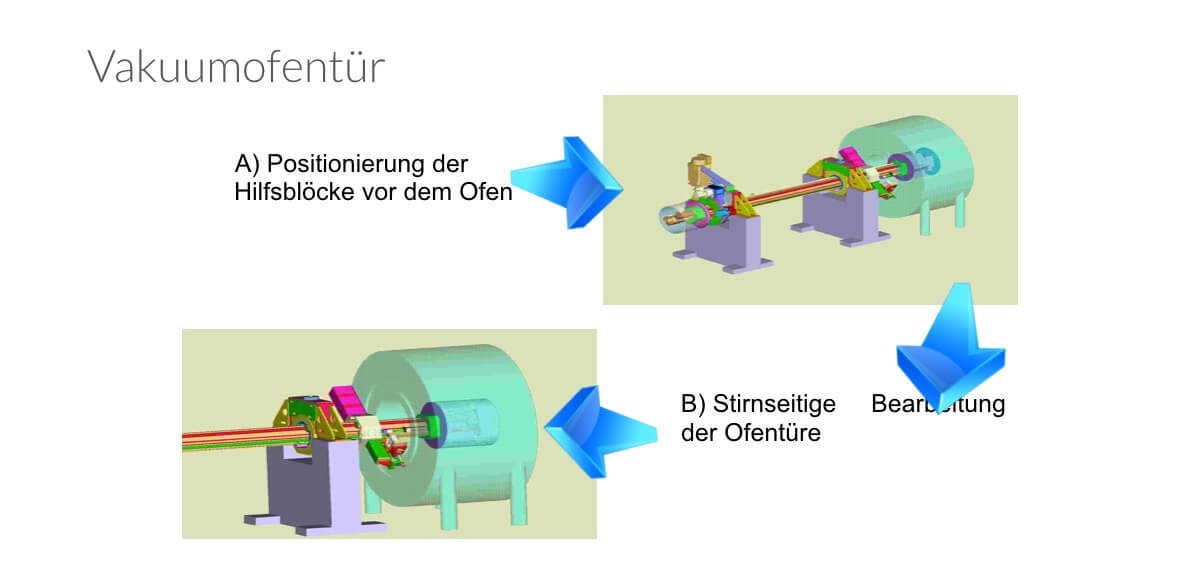

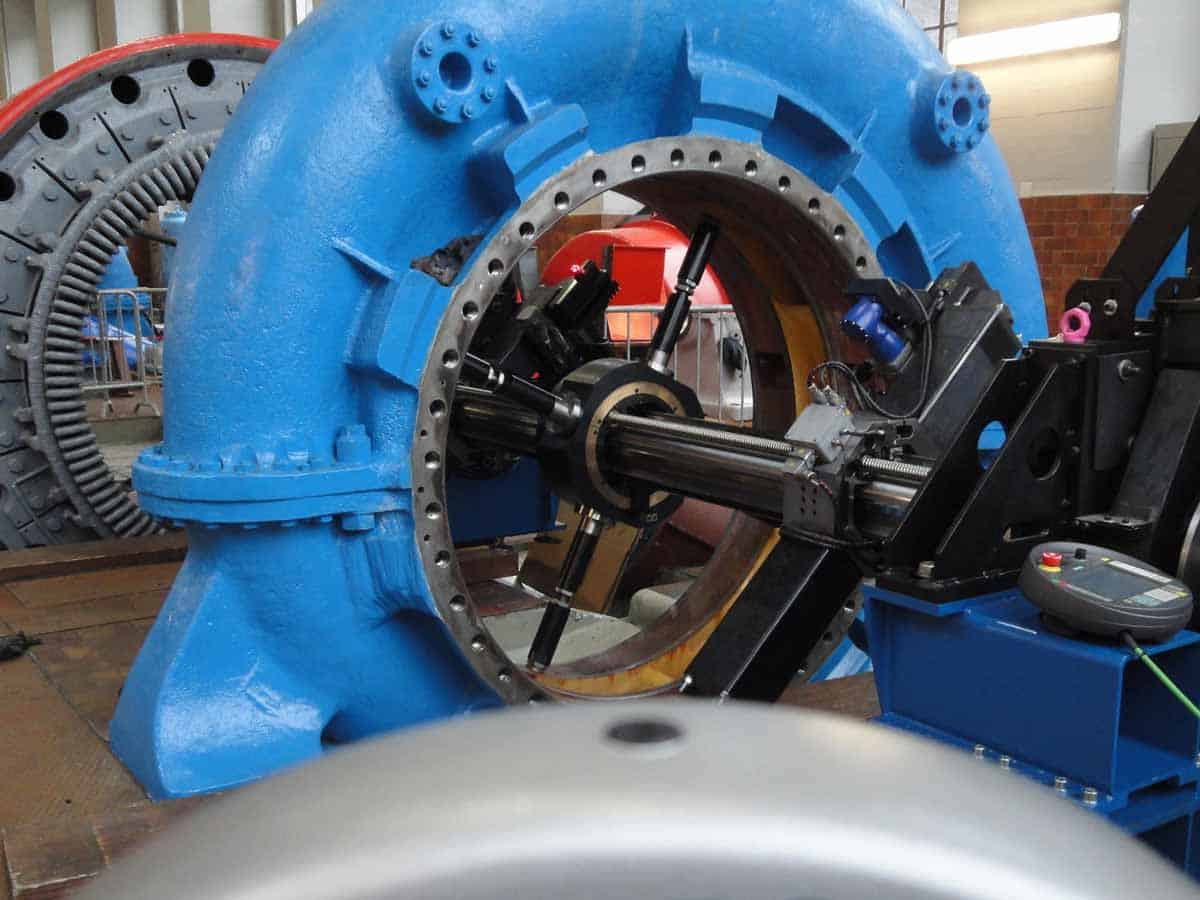

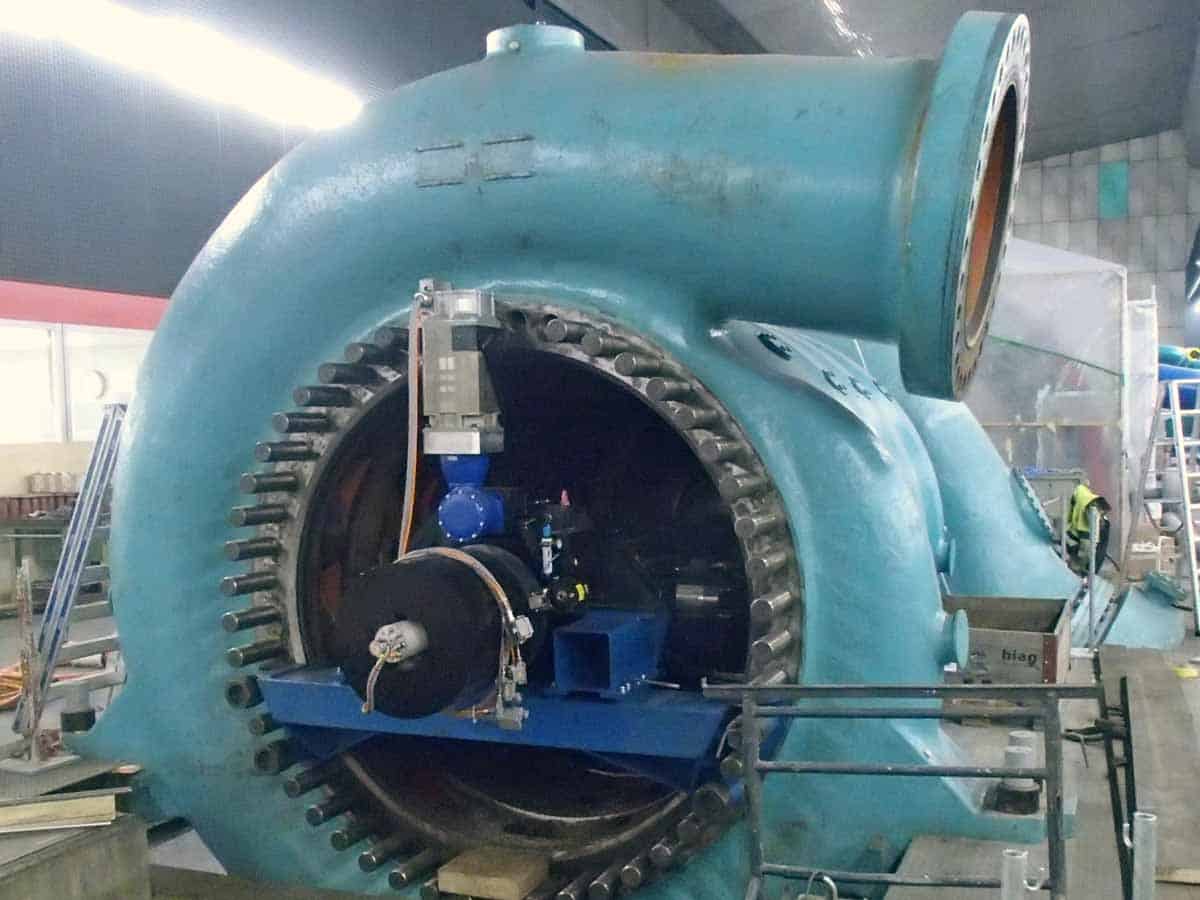

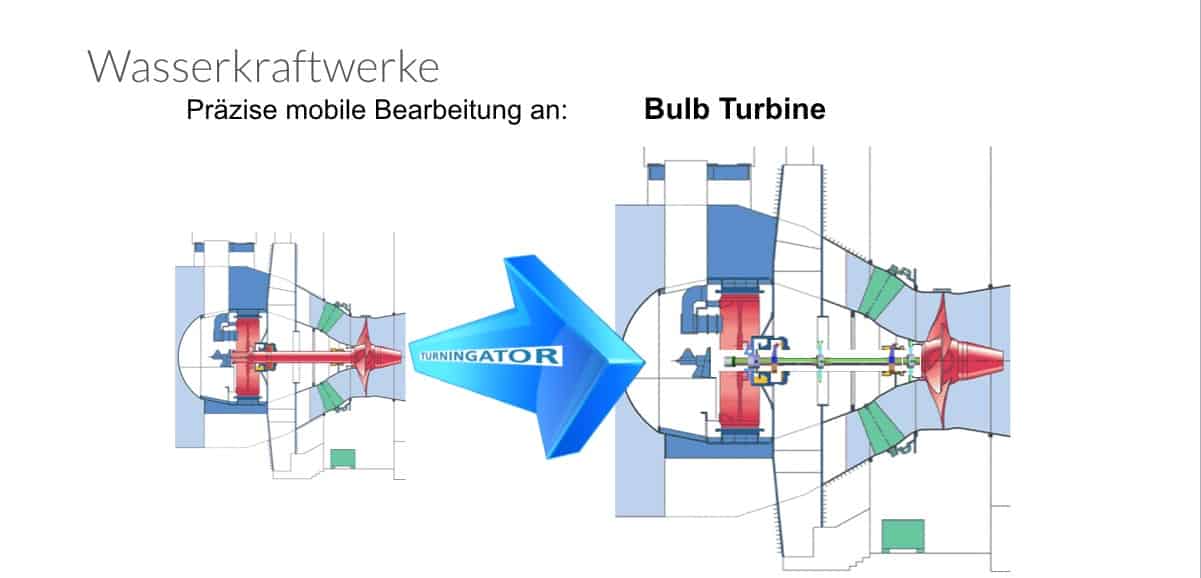

The mobile CNC processing center Turningator is an innovative solution to quickly achieve targeted efficiency’s in power plants. These versatile mobileCNC machining centers enables on-site machining of heavy turbine housings and offer counting benefits as shorter turbine downtimes and no transport costs.

Technical specifications

Drive and Control

• Control: Siemens 840 D

• Drive system: applied torque 2500Nm – 15’000 Nm

• Power: TURNINGATOR 2000 – 28kW / TURNINGATOR 4000 63kW

• Frequency 50 Hz / 60 Hz

• Ramp-up time: 0-70 [1/min] in 2.5 sec

• Drive system: applied torque 2500Nm – 15’000 Nm

• Power: TURNINGATOR 2000 – 28kW / TURNINGATOR 4000 63kW

• Frequency 50 Hz / 60 Hz

• Ramp-up time: 0-70 [1/min] in 2.5 sec

Processing

• Cutting speed 350 m/min (13’780in/min)

• Due to the high cutting speeds, state-of-the-art cutting tools can be used.

• Surface roughness: Ra 0.8 – Ra 0.4

• Cutting depth: 4mm – cast

3mm – steel

• feed depending on several factors such as tool, material, depth of cut and stability

• Chip volume in liters per hour: 0.42 [dm3 / min] = 25.0 [dm3 / hr] (0.3g/h)

• Threads and contours according to CNC program

• Due to the high cutting speeds, state-of-the-art cutting tools can be used.

• Surface roughness: Ra 0.8 – Ra 0.4

• Cutting depth: 4mm – cast

3mm – steel

• feed depending on several factors such as tool, material, depth of cut and stability

• Chip volume in liters per hour: 0.42 [dm3 / min] = 25.0 [dm3 / hr] (0.3g/h)

• Threads and contours according to CNC program

Precision

• ISO H7 can be maintained

• Positions are fed back to the controller via the rotary encoder

• Exact positions do through glass ruler positioning.

• Direct measuring system based on a linear guide

• Machine accuracy according to VDI / DGQ 3441

• Positions are fed back to the controller via the rotary encoder

• Exact positions do through glass ruler positioning.

• Direct measuring system based on a linear guide

• Machine accuracy according to VDI / DGQ 3441

Specified accuracy are subject to customer compliance with Wysshus installation specification and installation instructions. The accuracy depends strongly on external thermal influences. The specified accuracy is measured in the temperature range of 21 ° +/- 1 ° with a max. Temperature gradients of 0.4 ° per hour. In divergent environmental conditions we recommend independent Faro or Leica metrology for machining support.

Weight

Weight of individual models

TURNINGATOR 2000: approx. 3000 kg

TURNINGATOR 4000: approx. 6000 kg

TURNINGATOR 6000: approx. 8000 kg

Dimensions

TURNINGATOR 2000

| Machining | |

| Diameter: | 600 mm – 2’400 mm (23’’ – 95”) |

| Length: | 1’000 – 6’000 mm (39” – 236”) |

| Speed: | 70 rpm |

| Drive shaft: | Ø 200 mm (8”) |

| Torque: | 2’500 Nm |

TURNINGATOR 4000

| Machining | |

| Diameter: | 1’400 mm – 5’200 mm (55“ – 205“) |

| Length: | 2’000 – 8’000 mm (79” – 315”) |

| Speed: | 30 rpm |

| Drive shaft: | Ø 600 mm (24”) |

| Torque: | 7’500 Nm |

TURNINGATOR 6000

| Machining | |

| Diameter: | 2’000 mm – 8’000 mm (79“ – 315“) |

| Length: | 3’000 – 10’000 mm (118” – 394”) |

| Speed: | 20 rpm |

| Drive shaft: | Ø 700 mm (28”) |

| Torque: | 15’000 Nm |

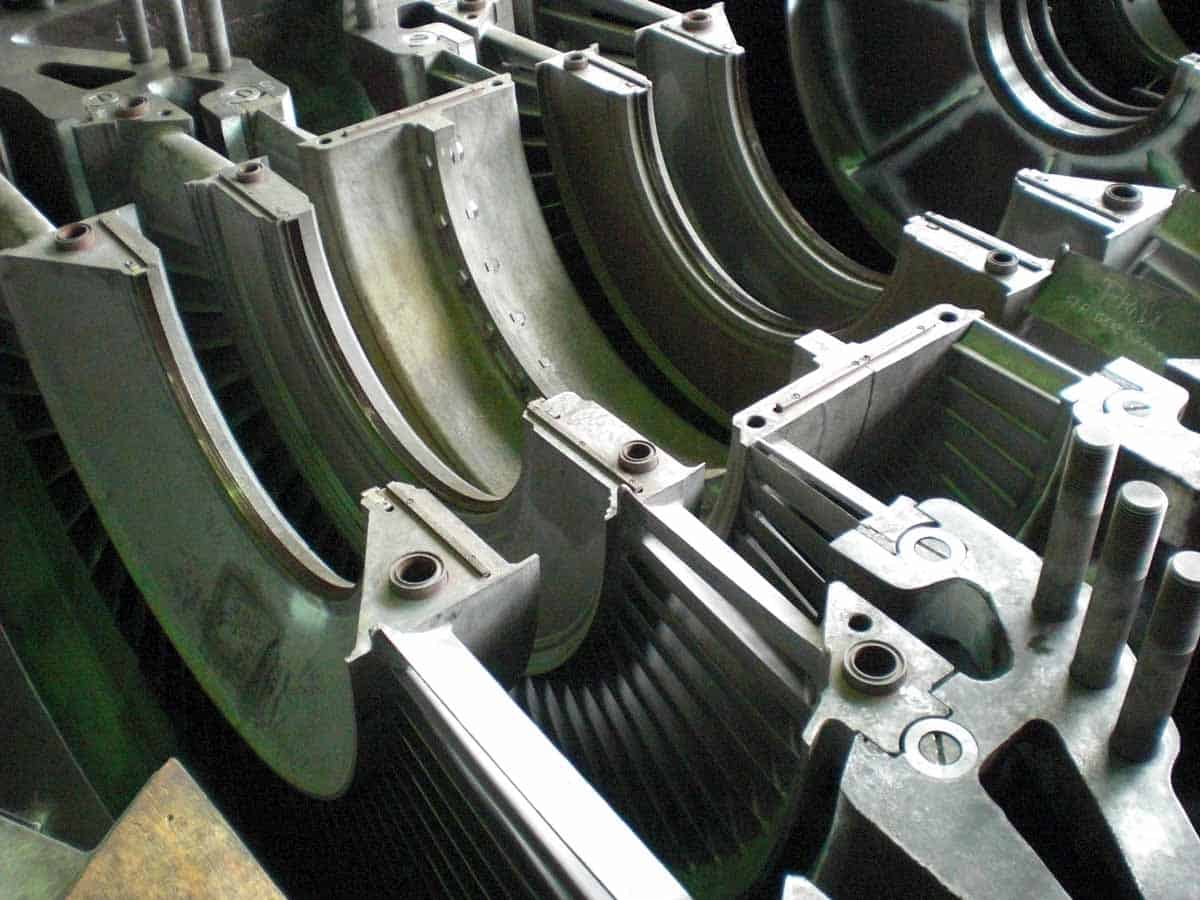

Applications

Turningator News

YOUR NEXT STEP

Get in touch with us!

We’re looking forward to an creative exchange with you

You already have the “no”, with us you’ll get the “yes”!

Phone: +41 79 347 43 03

Teams (Skype): markus.havrda@wysshus.com

Email: markus.havrda@turningator.com

TEAMS (SKYPE)

We take advantage of communication via Skype.